benefits of cnc machines CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an . $64.99

0 · disadvantages of cnc milling

1 · disadvantages of cnc machines

2 · cnc milling advantages and disadvantages

3 · cnc machining advantages and disadvantages

4 · cnc machine pros and cons

5 · advantages of cnc milling machine

6 · advantages and disadvantages of cnc

7 · advantages and disadvantages milling process

This Rhino Box is the most versatile box on the market. It has ten (10) potential openings. It can be used as a catch basin, distribution box, pump chamber, meter pit, and much more. The Polylok 24" Rhino Box makes even the toughest applications a breeze with its strength and versatility! Accepts 6" pipe with the use of Polylok 6" grommets!

disadvantages of cnc milling

CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an .

disadvantages of cnc machines

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

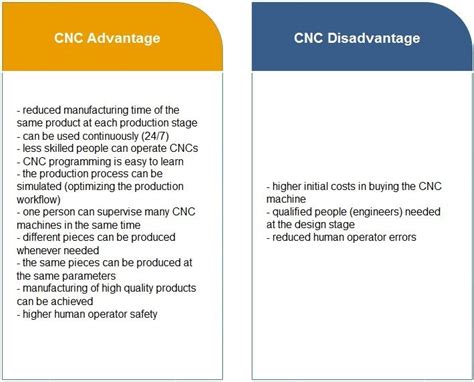

Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the .

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, .

Understanding CNC machining is vital in today’s manufacturing landscape, where efficiency, precision, and adaptability are required for lasting success. Industries that demand .

cnc milling advantages and disadvantages

CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries. Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain. Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal.

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, eliminating the risk of human error.

Understanding CNC machining is vital in today’s manufacturing landscape, where efficiency, precision, and adaptability are required for lasting success. Industries that demand components meet tight tolerance and function reliably are increasingly choosing CNC machining over other methods. CNC machining has revolutionised manufacturing with its numerous CNC machine advantages when compared to conventional machining. By replacing manual processes with computer numerical control, it offers precision, consistency, .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machines have strong adaptability to processing objects, high processing accuracy, stable processing quality, high productivity, high reliability, and can improve working conditions. The CNC unit is responsible for the operation and monitoring of CNC machine tools and serves as its brain.

Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, eliminating the risk of human error.

descargar real steel boxing champions hackeado

cnc machining advantages and disadvantages

cnc machine pros and cons

advantages of cnc milling machine

See more at: http://www.goengineer.com/products/solidworks/Learn how to get started with SOLIDWORKS Sheet Metal. Whether you have just started using SOLIDWOR.

benefits of cnc machines|cnc milling advantages and disadvantages